365betapp下载

Optimizing pre- and intermediate cleaning of powertrain parts in machining lines

蒸汽,而不是压缩空气,在MQL过程中也很有效

在汽车发动机和变速器生产线, 在加工步骤之间清洗零件现在是最先进的做法. Often this is done with compressed air, which needs to be generated at a high expense of energy. One favourable alternative from the perspective of operating costs consists in steam cleaning using Ecoclean's EcoCsteam system. This solution can also be integrated into production lines for pre-cleaning parts machined by the minimum quantity lubrication (MQL) method. The result will be a tangibly increased bath life in downstream aqueous cleaning.

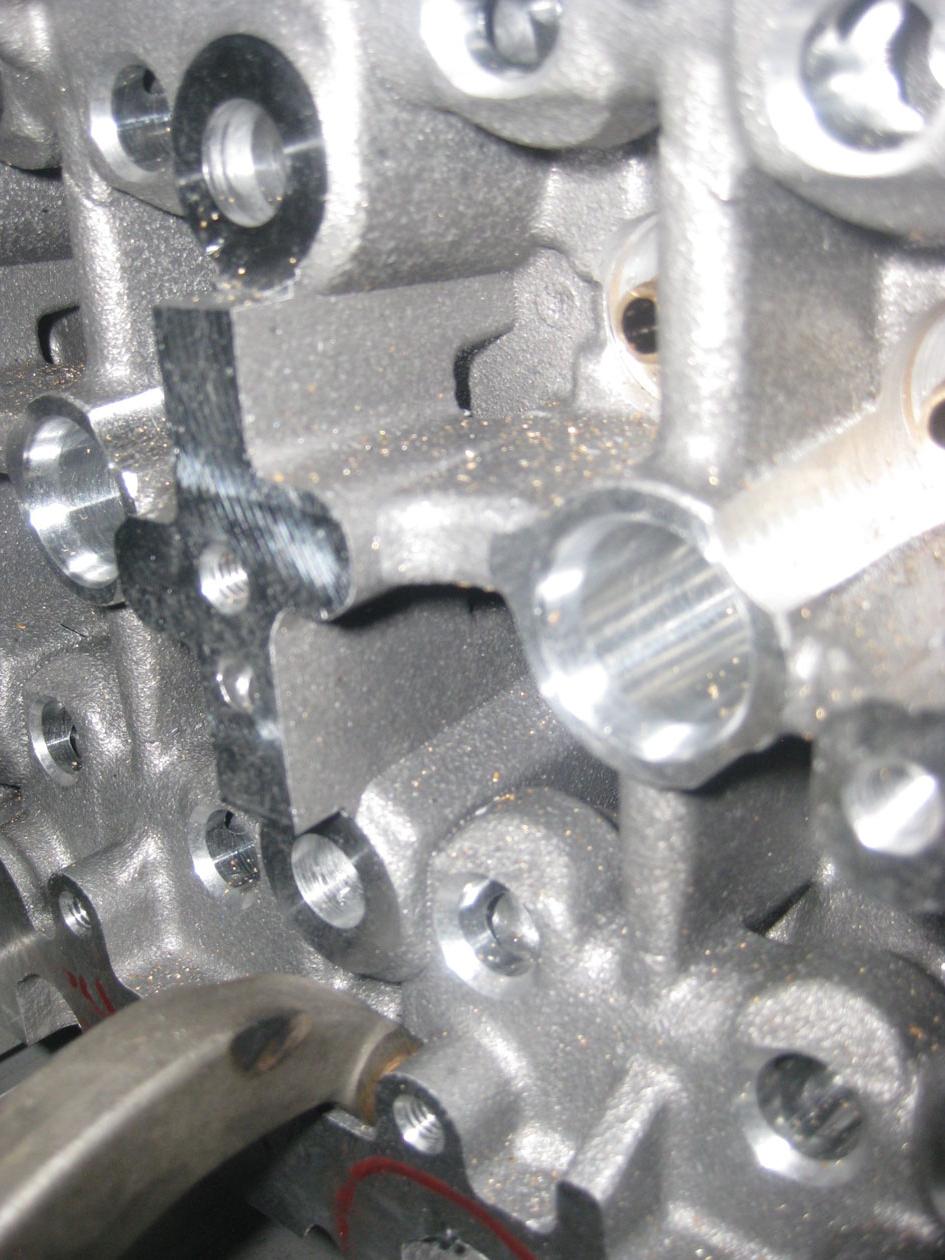

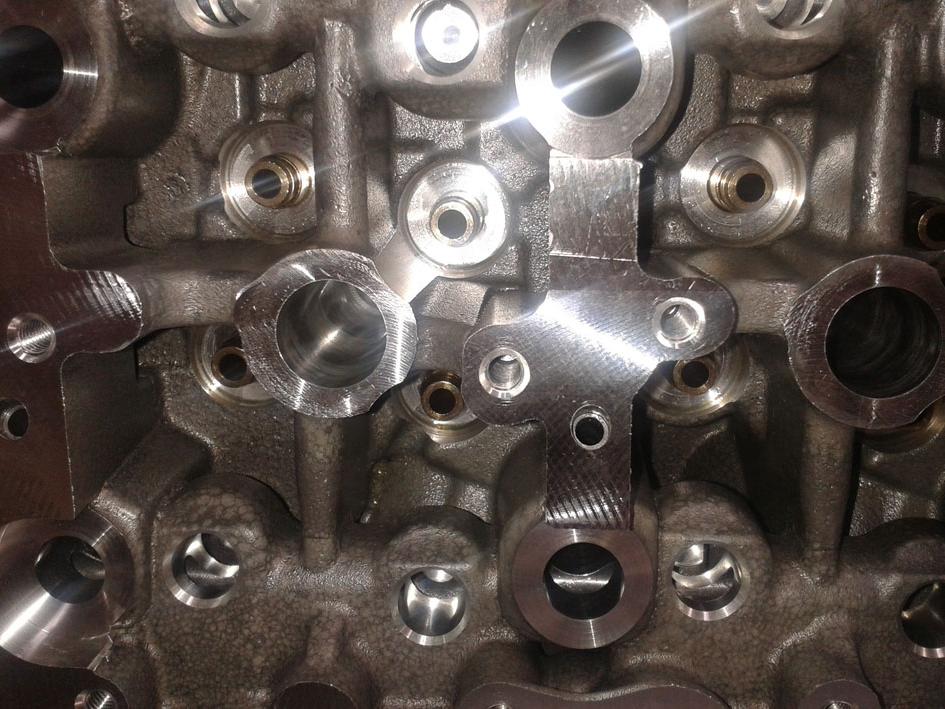

Minimum quantity lubrication (MQL) stands for a trend that is rapidly gaining ground in the manufacture of aluminium and steel automotive powertrain components. 这不足为奇, since the ultra-sparing application of a mix of fine oil droplets and compressed air in machining, e.g., crankcases and crankshafts, cylinder heads and connecting rods provides substantial energy savings. 它还消除了与供应相关的昂贵和复杂的功能, 处理, 冷却剂的修复和储存. A further advantage of MQL is that it improves work convenience by avoiding personnel exposure to heavily oil-laden air. 总共。, the technique provides many benefits underpinning the automotive industry's advance towards sustainability.

但哪里有光,哪里就有阴影. 在MQL过程中,缺点在于部分清理. 工件上残留的润滑剂, 虽然数量很少, 极粘于表面, 将碎片和颗粒粘合到位, 可以说. This effect calls for a significant extra effort in the subsequent aqueous cleaning cycle, 导致浴槽寿命大大降低. 而不是持续四周, 这是基于标准冷却剂的机械加工过程中常见的, the bath fluids must be changed after as little as one week in the case of a MQL process.

This translates not just into higher cleaning costs but also into reduced plant availability. It this therefore only logical that OEM and powertrain part manufacturers should be aiming for a solution to minimize contaminant carryover into the cleaning system so as to prolong the service life of the cleaning bath again.

使用湿蒸汽进行高效的预清洗

The compressed air systems commonly used for in-process cleaning are virtually ineffective against such slight but highly adhesive contamination. An efficient alternative is to pre-clean the workpieces with Ecoclean's steam-cleaning system EcoCsteam. It relies on the use of hot wet steam in conjunction with a high-velocity airflow. 由于蒸汽清洗操作很容易实现自动化, the technology can be integrated directly into the manufacturing line as a compact modular system, 在规定的周期内提供预清洗.

不像传统的锅炉式系统, EcoCsteam的工作原理是通过水流加热. Water is passed through a pipe system equipped with heating coils which heat it to the optimum temperature for dislodging the MQL process residue. 蒸汽的含水率也同样适应于污染. This special steam generating method not only minimizes water demand to a mere 250 – 300 milliliters per hour; it also provides steam of unchanging quantity and quality, 并且在清洗过程中具有恒定的性能. 为了增强清洁性能,可以添加清洗剂. The high-velocity airflow serving as a carrier and accelerating medium is produced by a turbo-fan. 这比压缩空气系统的运行成本要低得多.

水和蒸汽吞吐量, heat input and air flow rates can be precisely adjusted by the EcoCsteam system's controller and are continuously monitored and adapted by the PLC.

浴龄加倍

In the EcoCsteam process, the transformation of water to steam occurs only at the nozzle outlet. 被高速气流包围, 然后蒸汽喷射集中在被污染的表面. 撞击后,湿蒸汽改变MQL残留物的粘度. The latter is atomized into ultra-fine droplets and dislodged from the workpiece surface by the airflow, 还有微粒和碎片. The substances thus removed is fed to an integrated filtration and 处理 unit. 在这里, chips are filtered out and collected in a separate container while the water can be reconditioned or discharged. Alternatively, the steam cleaning module may be connected to the user's own 处理 system.

测试表明, 取决于给定曲面的复杂性, at least 50% of the adhesive MQL residue can be removed by the steam cleaning process. 因此,进入清洗系统的异物的携带量减少了一半. 因此,清洗浴的使用寿命增加了一倍. This leads to a tangible reduction in costs per part: Assuming that 50 per cent of the cleaning costs are expended on the 处理 of used fluid as well as on chemicals, 新浴室的水和能源, the doubled fluid lifetime translates into savings of around 25 per cent per cleaned part.

也有利于冷却剂污染部件的中间清洗

Optimum intermediate cleaning is also achieved between machining cycles using conventional coolants. Compared to solutions relying on costly compressed air, the EcoCsteam system saves operating costs. 除了, the steam cleaning technology requires less floorspace than a belt cleaning system and distinguishes itself by exceptionally short cycle times. 此外, 清洗过程中不使用化学药品, using only water with or without the addition of an optional corrosion inhibitor.

作为一种永远干净的媒介, steam also opens up a number of further application options in the production of power train components. 一个例子是对抛光表面的一尘不染的清洁.g., 曲轴或凸轮轴的, prior to their visual inspection by an automatic optical image recognition system.

作者:Doris Schulz